As we seek to mitigate the effects of our changing climate, the choices we make in construction will have an impact that will last generations. The way we build, the materials we choose today are of paramount importance for our tomorrow. Only materials with both environmental credentials and a proven track record can truly be relied upon to deliver the security and green growth needed for a healthier, more resilient society.

With its unique ability to conserve resources and stand the test of time, galvanized steel has been proving its worth for centuries, long before climate change became the critical concern it is today. In fact, galvanized steel is one of the original green solutions, silently playing a pivotal role in shaping more sustainable transport, public spaces, energy infrastructure and much more, for many decades. Coupled with intelligent, ambitious design, galvanized steel can go even farther to help us futureproof our built environment and deliver the sustainable future we need.

Why is galvanized steel such a sustainable choice?

Primarily galvanized steel possesses valuable circular benefits. In the simplest terms a tough, galvanized coating protects a vital asset – steel – enabling it to be used repeatedly, without maintenance or repair. It also lasts a very long time. The benefits of choosing this reliable, proven coating are numerous:

Resource conservation

The longevity offered by galvanizing aligns with the new circular economy and means that additional construction is avoided. By using galvanized steel, we can build structures and fabricate components that endure, and which offer multiple lifecycles. Whether it retains its original usage or whether we choose to adapt a structure or component, choosing galvanized steel means the original construction material is kept in a constant loop of use. In so doing, we avoid additional, unnecessary carbon being introduced into the closed circular system.

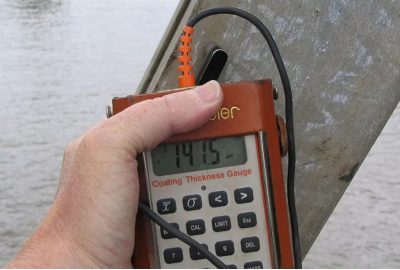

Maintenance reduction

Due to the unique metallurgical bond produced by hot dip galvanizing, a galvanized coating is both resilient to handling and environmental stress, and will deliver a long lifespan. Such durability and resilience minimise maintenance and the associated dangers and costs. As a result, galvanized steel is an excellent construction material for projects that need to offer reliable public services, and those that must maintain a state of scheduled operation. In reducing maintenance, we reduce emissions, avoid downtime, and protect our workforce too.

Reusability

A galvanized coating is a system of tough metallurgically bonded alloys which are resistant to the mechanical demands of mounting and demounting. This makes galvanized steel components highly adaptable. With future advances in systems that catalogue and track the reuse of construction materials, a single component can be used multiple times, delivering many lifecycles and lowering carbon footprint. Going forward, this is set to increase as we fully embrace a circular economy.

Value in Modular Design

The hot dip galvanizing process is highly reliable and offers coverage and performance that can be infinitely repeated. This process facilitates the standardization of components and off-site construction. As modular design forms a larger part of our built environment, the ability to produce uniform components that can be successfully reused, will be increasingly valued. By combining galvanized steel with modular design, we can create a flexible, responsive public spaces and infrastructure, adaptable to changes in usage and need. Outstanding projects throughout Europe and the UK show modular construction doesn’t have to be at the expense of ambition or design quality.

200 years and counting

Overall, by conserving resources and reducing maintenance, galvanized steel helps reduce carbon footprint and has been doing so for nearly two hundred years. The simpler the installation and the longer a material can stay in place without maintenance, the more energy efficient the component becomes. In 2021 researchers estimated that corroded steel replacement was responsible for 1.6 to 3.4% of global emissions.[1] Galvanizing steel helps avoid this expensive environmental liability and means structures and components can be kept in a cycle of constant use. As we embrace the need for more climate resilient, cleaner ways of living, we should keep looking to our original green solutions. We should remind ourselves how they perform today and imagine how they can help build our tomorrow.

[1] https://www.azocleantech.com/news.aspx?newsID=32852#:~:text=If%20measures%20to%20reduce%20steel%27s,to%209%25%20of%20that%20total.

Join the conversation

Make a comment