Hot Dip Galvanizing offers unparalleled protection against rust, extending the lifespan of structures and products in a way that naturally aligns with circular goals. As the UK and Ireland begin to embrace circular practices and place greater emphasis on longevity and reusability, galvanized steel is emerging as a valuable asset and an original green solution. Recent projects from around the UK and Europe evidence that hot dip galvanizing helps prevent costly corrosion. They also show us that galvanized steel:

- Is a robust circular material

- Produces adaptable structures and components that can mitigate the results of climate change

- Is a lower carbon solution over the longer term

So, what are some of the ways that galvanized steel supports us in the journey towards a circular future?

1. Extending lifespan means smaller carbon footprint

Hot dip galvanizing significantly enhances the durability and longevity of steel structures and products. The coating starts working immediately upon application and can last 100 years or more, outperforming many other traditional coating methods. This longevity minimizes the need for further carbon costly construction or frequent replacements and can lead to substantial environmental benefits over the long-term.

2. A robust coating means greater versatility

As a durable and robust finish, a galvanized coating will withstand multiple mounting and demounting cycles, supporting adaptable design and flexible usage. In a circular future the capacity to re-use, re-model and remount structures will lead to greater adaptability, reduce consumption, and avoid wastage.

3. Zero Maintenance

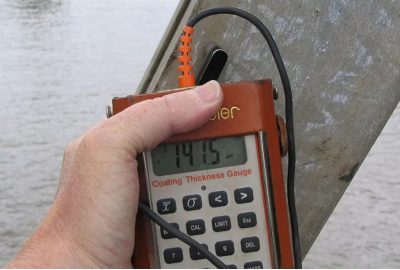

Unlike other coatings that require regular maintenance to prevent corrosion, galvanized steel can be left in situ and trusted to perform. Once galvanized, the steel is protected throughout its lifespan, eliminating the need for frequent touch-ups or reapplication of coatings. This no-maintenance requirement not only saves time and unwanted disruption, but it also reduces the consumption of precious resources and helps reduce carbon footprint.

Galvanized steel is a circular material that supports innovation and sustainability. Its unrivalled corrosion resistance, durability, low maintenance requirements, and cost-effectiveness make it an invaluable choice when seeking long-lasting, environmentally considerate solutions. By embracing galvanized steel, we can build a rust-free today and pave the way for a circular future where resources are conserved, waste is minimized, and our structures and products stand the test of time. So, how will you harness the circular potential of galvanized steel? How can your projects use this durable, circular material to help build a sustainable and resilient tomorrow?

Join the conversation

Make a comment