In an ideal circular world, components are kept in a continued cycle of perpetual use, reused for unlimited life cycles – a closed loop with an optimal use of resources, labour and raw materials. Currently for the construction sector, this remains a goal. In reality we are still tackling end of use scenarios for products, materials and structures, making recycling still very much part of the sustainability landscape.

Within the hierarchy of processes that make up a true circular approach to construction, recycling is an important process that occurs only once all other circular methods have been exhausted. It offers a final solution to keep raw materials within the circular economy but can carry a CO2 burden.

Recycling in the new circular climate means optimising any burden and finding a way to retain value to make something that lasts. Fortunately, steel and zinc can be readily recycled and are not downgraded. Galvanized steel undergoes closed-loop recycling – retaining its value continually, making products and components that last a lifetime.

LCA or life cycle analysis studies show that the type of recycling that a product undergoes is important in terms of determining its end-of-life credentials. Recycling can either be ‘open-loop’ (often termed downcycling) or ‘closed-loop’ depending on the type of change that the materials are subject to. The UK Steel industry defines the two approaches as follows:

- Open loop recycling involves the conversion of material from one product life cycle into another product life cycle. This usually involves a change in the inherent properties of the material itself (often a degradation in quality). For example, recycling plastic bottles into plastic drainage pipes. Often this is called downcycling or reprocessing.

- Closed loop recycling describes the recycling of a product into an identical product, for example recycling a steel beam into another steel beam.

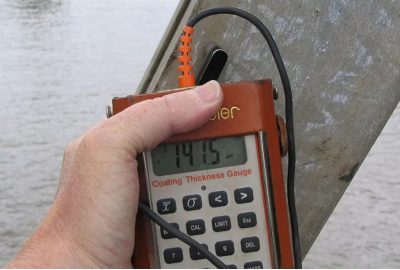

Our recent publication Galvanized Steel And Sustainable Construction: Solutions For A Circular Economy, released in conjunction with our European counterparts, EGGA, explains the current process for recycling galvanized steel. It shows how at end of life – and if reuse is not feasible – galvanized steel can be recycled easily with other steel scrap in an electric arc furnace (EAF) steel production process. Any zinc remaining from the coating volatilises early in the steel recycling process and is collected in the electric arc furnace dust, this is then recycled in specialist facilities and often returns to refined zinc production.

Since the early 1980s, a well-established process has been used to process EAF dusts which contain valuable zinc and other elements. An impressive 98% of EAF dusts produced by Europe’s steelmakers are recycled.

Overall, recycling galvanized steel produces materials with significant commercial and industrial value, which can potentially find themselves once more within the circular economy: negligible waste, value retained, true circularity in action.

For more information, visit Recycling Galvanized Steel

The guide, Galvanized Steel and Sustainable Construction: Solutions for a Circular Economy, is available on request as a download or in print

Join the conversation

Make a comment