Rail networks have always stood as symbols of progress, connecting communities and propelling societies forward. The design and delivery of HS2 is no different, presenting a significant opportunity for the UK to showcase a project of world-class, climate-resilient excellence.

Long gone are memories of rusting railway infrastructure. In their place the prospect of a shining new railway, exploiting the benefits of circular, adaptable design. In combining cutting-edge engineering with sustainable materials, the UK could set a global standard for climate-conscious infrastructure. The road to getting there means innovating with materials that are proven, secure and which will benefit passengers and business for generations to come.

HS2 future: galvanized steel is a material you can trust

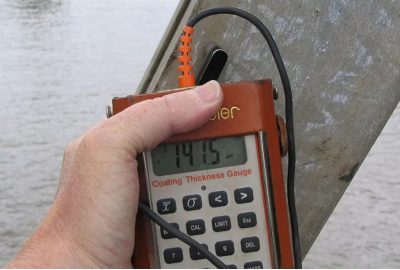

Galvanized steel offers measurable and predictable performance. The lifespan of a galvanized coating can be easily and correctly forecast, and there will be no unexpected surprises. Ensuring uniform protection, the process of hot dip galvanizing, provides repeatable and quantifiable results which can last over 100years – a reliability backed by decades of data.

Galvanized steel has long supported the UK rail network because it works immediately upon application, is fail safe and offers unbeatable corrosion protection. From overhead line equipment and gantries, to multiple uses of structural steelwork, galvanized steel offers a true zero-maintenance solution. It is easy to inspect and unlike other corrosion protection systems, will not hide or disguise underlying corrosion. As a consequence, it plays a valuable role in reducing delays due to component failure or scheduled works, and means that galvanized steel structures reduce carbon footprint, deliver security, and distil confidence.

The way forward is circular

The delivery of HS2 is an historic opportunity for the UK to be a global frontrunner in sustainable, climate-resilient infrastructure. In the face of climate challenges, HS2 stands as a testament to the nation’s commitment to building a world-class transport system that not only meets needs today but also sets the bar for environmentally conscious engineering. Within a UK decarbonisation framework, the use of circular materials will become increasingly important. We will need to choose materials that endure, conserve resources, and which offer multiple lifecycles. As the demand for cleaner, greener public spaces grows, so does the call to use trustworthy materials which do not quite literally cost the earth. Galvanized steel structures offer these benefits and choosing galvanized steel means that valuable construction materials can be kept in a stream of constant use.

With a robust network of galvanizing plants strategically placed across the UK, steel structures can be galvanized close to where they will be situated and transported economically and efficiently. This also means that the use of galvanized steel in rail projects goes to the heart of bolstering local supply chains.

With a robust network of galvanizing plants strategically placed across the UK, steel structures can be galvanized close to where they will be situated and transported economically and efficiently. This also means that the use of galvanized steel in rail projects goes to the heart of bolstering local supply chains.

A robust rail network is more than a means of transportation; it serves as the essential infrastructure for communities and fosters growth in local economies. This combined influence on both economic prosperity and local populations underscores the importance of sourcing circular materials that contribute to both the stability of critical infrastructure and the growth of local industries.

A recent publication Galvanized Steel: Keeping Decarbonisation on Track details leading examples of how these circular principles are already contributing to railway infrastructure. For information on how they can be implemented into further rail design and construction, a copy of the guide can be downloaded here.

The connection between technological innovation and societal development is etched into the very tracks that crisscross the UK landscape. We should make sure we innovate with materials that are proven, secure and which will benefit our communities for many future generations.

This editorial is featured in Rail Professional UK February 2024 issue, page 98 and you can access it here.

Join the conversation

Make a comment