A circular economy tackles the issue of finite resources by considering all raw materials as valuable assets and using them sparingly. As a durable method of corrosion protection, a galvanized coating reduces the whole life carbon footprint of buildings and components through avoidance of maintenance.

Reducing whole life carbon footprint

Lack of attention to optimal corrosion protection can leave a damaging legacy of repeated maintenance costs which can significantly increase the lifecycle carbon footprint of buildings and infrastructure. The repeated painting of steel structures is an environmental and economic burden that can be avoided.

In addition to the lifecycle benefits of galvanizing steel, the efficient use of resources, is key to the circular economy. The steel industry has developed high-strength and advanced high-strength steel grades for many applications. These grades contribute to the light-weighting of applications, from wind turbines to construction panels and automobiles, as less steel is needed to provide the same strength and functionality. By providing maximum levels of corrosion protection, galvanizing allows for more efficient design solutions to be used.

Whether it is by reducing maintenance operations or avoiding the premature replacement of steel products, galvanizing will reduce the embodied carbon of construction.

Galvanizing’s ability to optimise the durability of steel structures and components has important environmental, economic and social advantages. There are high economic and environmental costs associated with the repeated maintenance painting of steel structures. These burdens can be significantly reduced by an initial investment in long-term protection.

The long-term durability provided by galvanizing is achieved at relatively low environmental burden in terms of energy and other globally relevant impacts, especially when compared to the energy value of the steel it is protecting. Whether it is by reducing maintenance operations or avoiding the premature replacement of steel products, galvanizing will reduce the embodied carbon of construction.

Life Cycle Comparison for steel-framed car park over 60 year life

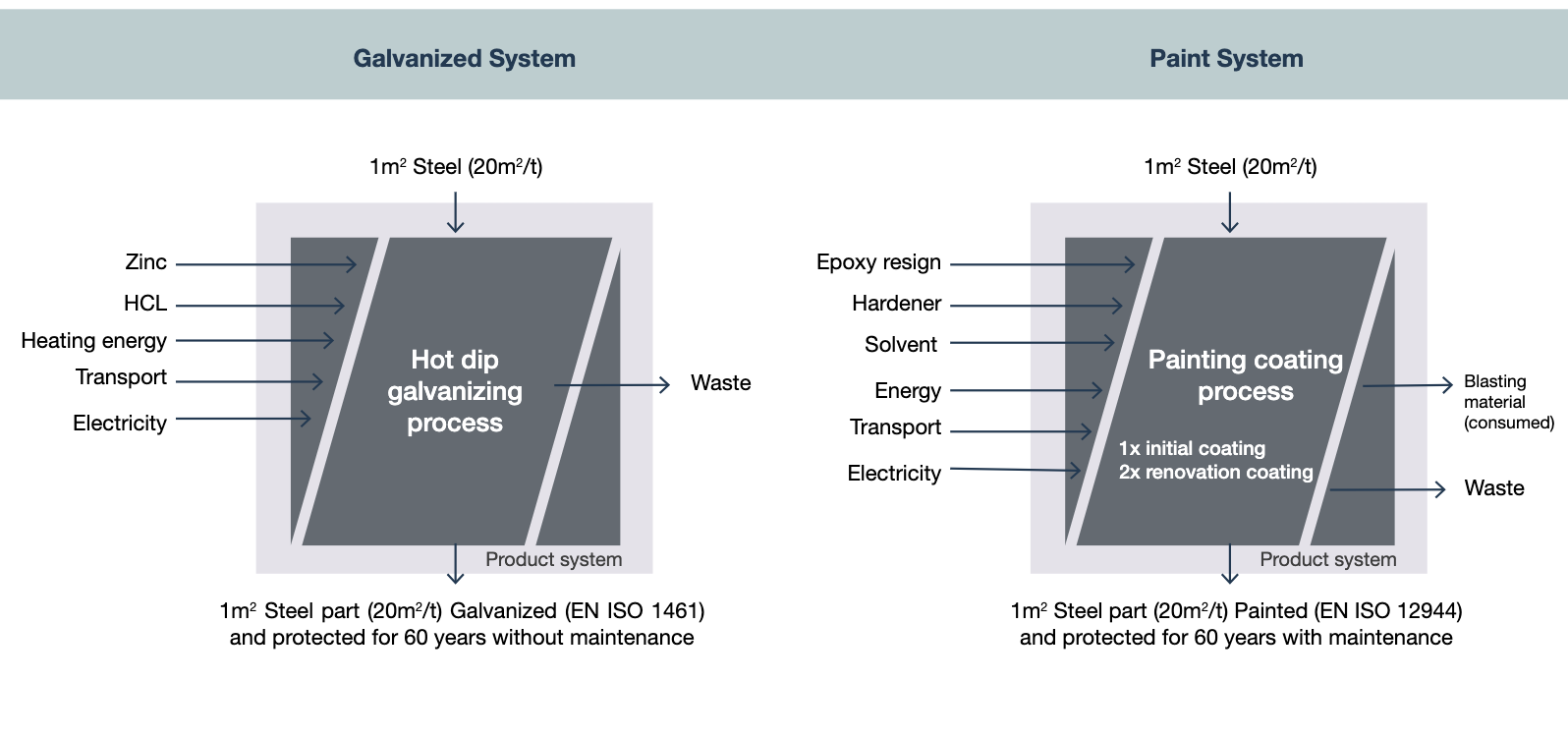

A study by the Environmental Technology Systems Department of the Institute for Environmental Protection Technology at the Technical University of Berlin involved a comparison between a paint coating (EN ISO 12944) and hot dip galvanizing (EN ISO 1461) for a steel car park in a life cycle assessment (LCA).

Central to LCA comparisons is the functional unit – the reference quantity for the comparison. An objective comparison cannot be made without identical comparison variables.

The way these values were defined in the study was that the two systems had to provide corrosion prevention for a steel structure which was to be used for 60 years, and which was applied to a steel structure such as a multi-storey car park with a steel area amounting to 20 m²/t. It was assumed that the structure was externally exposed to a medium level of corrosion (corrosion category C3 from ISO 9223).

The hot dip galvanizing system is a ‘one-off’ corrosion prevention treatment by immersion in molten zinc. With a galvanized coating thickness for this example application of 100 μm and an average corrosion rate for category C3 of 1 μm/year, the calculated durability far exceeds the required 60 years.

To guarantee corrosion prevention for 60 years using the paint coating system, the components are first abrasion-blasted to remove any rust. Then they are painted in the works with a three-coat application with a total coating thickness of 240 μm. On-site maintenance operations are then needed after 20 and 40 years, involving partial cleaning and some renewal of the coating.

Summary of two Systems

Comparison between a paint coating (EN ISO 12944) and hot dip galvanizing (EN ISO 1461) for a steel car park life cycle assessment.

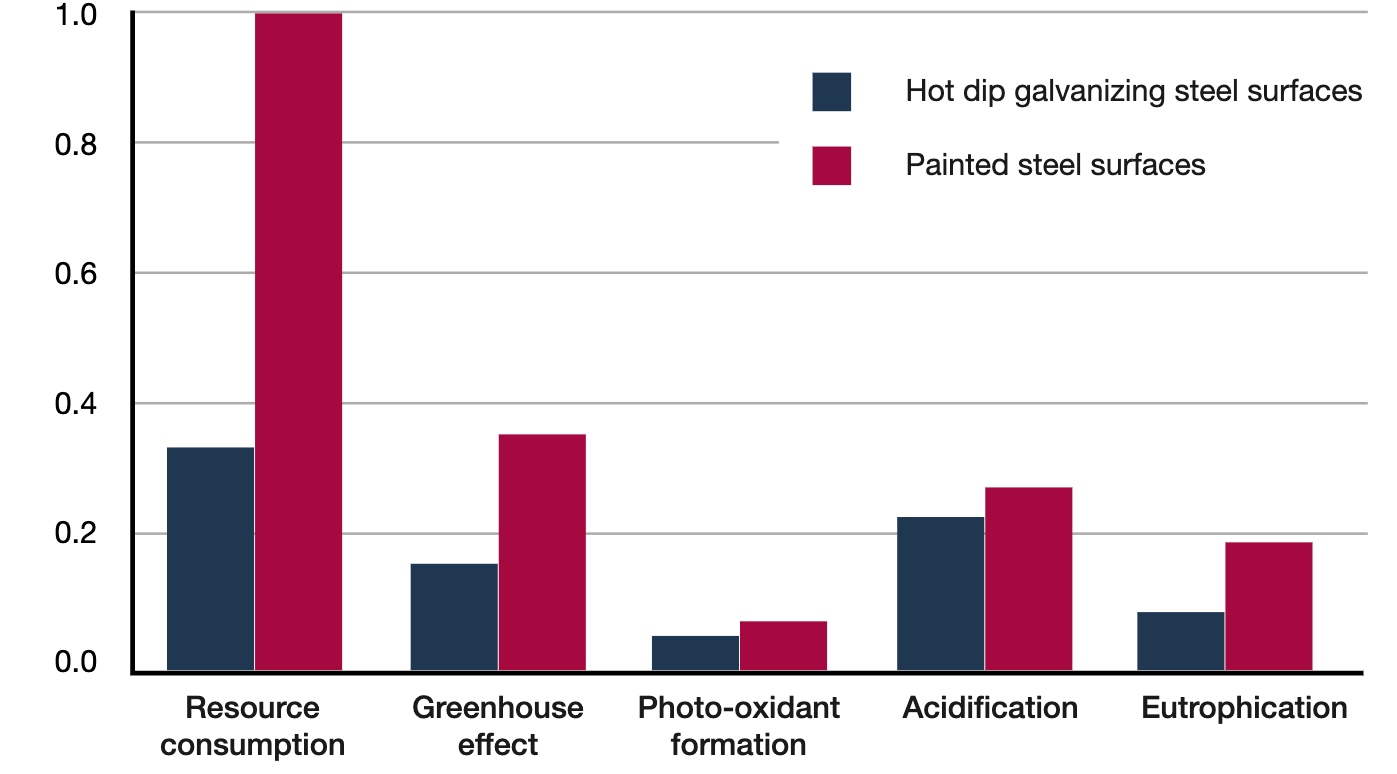

The results are represented by five different environmental impact categories. The chart below shows these environmental impacts. The results are normalised to the largest contributory factor (consumption of resources).

Comparison for steel-framed car park over 60 year life.

The contributory factors for the hot dip galvanizing system are lower in all effect categories than for the paint system. In several effect categories there are marked differences. In comparison with paint, hot dip galvanizing’s score in the category of eutrophication is only 18%, in the resource consumption category it is only 32%, and in relation to the greenhouse effect it is only 38%. Hot dip galvanizing is distinguished by lower consumption of resources and less pollution throughout its service life.

The study shows that life cycle assessment is a meaningful method, based on actual practice of ecological comparison of products. It brings out marked differences between two established corrosion prevention systems for steel structures. The hot dip galvanizing corrosion prevention system displays lower environmental impact for a steel structure with a long service life, as against a paint system.

Long service life and freedom from maintenance, the well known advantages of hot dip galvanizing, are the basis for the environmental benefits of the process. In this example, as shown in the table below, a saving of 57 tonnes of CO2 were achieved over the 60 year life of the car park.

The Eiffel Tower – A Maintenance Legacy

When Gustave Eiffel constructed his famous tower in 1889 for the International Exposition and centennial celebrations of the French Revolution, it was envisaged to be a temporary structure. Little did he know that it would still stand as the much-loved landmark of Paris over 130 years later.

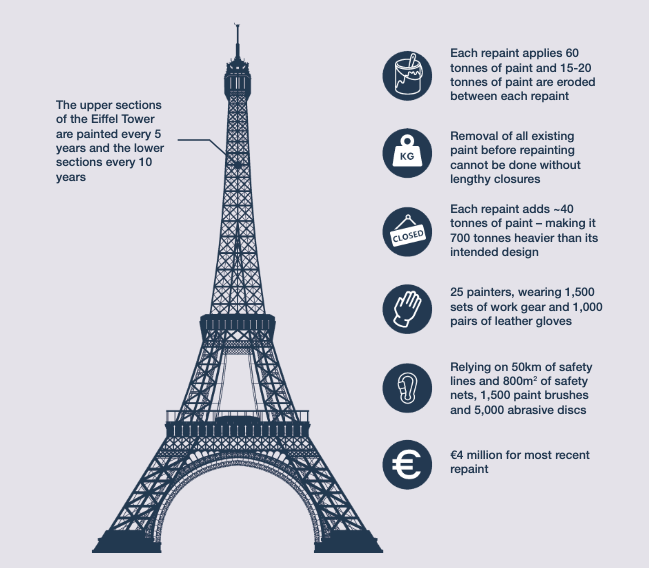

But this longevity has come at a price. The Eiffel Tower’s ironwork has been repainted 19 times and a maintenance painting cycle takes 18 months at a cost of €4 million. The repainting costs are estimated to be ~14% of the current construction cost of the tower.

It is the costs in resources, risks for worker safety and the structural consequences of this repeated painting that goes unseen by the millions of tourists that visit this iconic structure. With ~40 tonnes of residual paint added to the structure at every repaint, the structural consequences of this additional mass will eventually have to be solved. In recent painting programmes, it has been necessary to start to remove all 19 previous paint layers from certain areas of the tower to maintain its structural integrity.

A lesson for today’s structures which are far too often built without durability and avoidance of maintenance in mind.

________________

Reducing Carbon Footprint – Case Studies

Lydlinch Bridge

Location: Dorset

Structure Type: Callender-Hamilton Bridge

The old adage of size is not everything comes to mind when considering the history and performance of the Callender-Hamilton bridge at Two Fords, Lydlinch, Dorset.

As early as 1942 the Ministry of Defence was considering outline plans for the D-Day invasion. Where and when the landings would take place were top secret, but the speedy movement of the invasion force to the south coast ports was a common factor to all alternatives. One such route, the A357 through Dorset, Poole Harbour, needed to be improved.

At Lydlinch, the picturesque narrow stone bridge over the River Lyden would not withstand the weight of heavy tanks. In 1942 Canadian army engineers erected a temporary galvanized steel Callender-Hamilton bridge alongside the older structure. The tanks and heavy equipment were diverted over the galvanized bridge on their way to Europe.

________________

Cedar Brook

Location: Dublin

Architects: O’Mahony Pike

In 2003, Dublin City Council launched a design competition to secure a joint venture partnership that would build social and affordable housing on a 4 hectare council owned site to the west of the city.

The brief required the design of innovative high density, own door, family housing with surface parking and quality amenity spaces throughout. The housing would be economical to build but use innovative modern methods of construction to ensure speedy erection and ensure quality dwellings.

The competition was won by O’Mahony Pike, in collaboration with Park Developments and John Sisk and Sons. The development became known as Cedar Brook and on completion included 376 duplex units, apartments and family houses achieving a density of 94 units per hectare.

Images © Galvanizers Association.

________________

You may also be interested in: