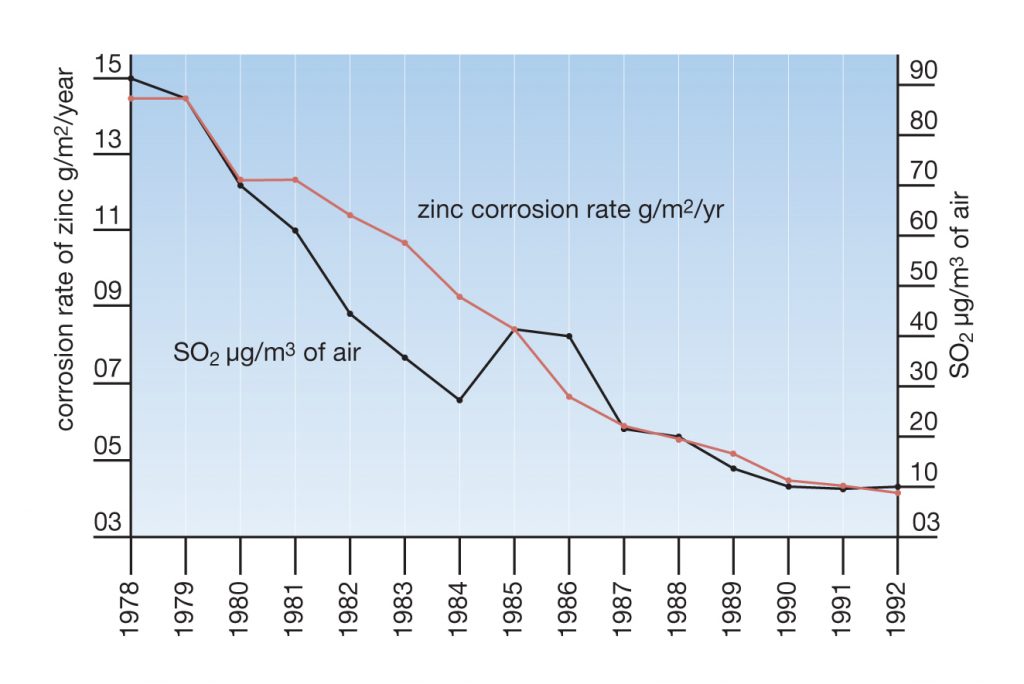

It is widely known that levels of atmospheric sulphur dioxide (SO2) have been falling for several decades. The results of the Atmospheric Corrosion Rate for Zinc demonstrate how the reduction in SO2 levels since 1991 has helped to increase the life expectancy of hot dip galvanized coatings.

This has a particular significance for those with the responsibility for sanctioning construction projects where whole life costs, longevity, and maintenance are important considerations.

The most important contaminant affecting zinc is sulphur dioxide (SO2) and it is the presence of SO2 which largely controls zinc’s atmospheric corrosion rate. It is widely documented that atmospheric SO2 levels have fallen significantly in most countries over the past decades.

Reduction in sulphur dioxide levels in Stockholm since 1978 and accompanying decrease in corrosion rate of zinc.

How long does it take for galvanized steel to rust?

The answer to this question depends on the environment that the galvanised steel structure is exposed to.

With average atmospheric zinc corrosion rates across the the UK and Ireland normally being less than 1µm per year, a typical 85µm coating can provide over 85 years of maintenance-free life. For further information click to see our corrosion map.

Galvanized steel in Southwold

“Galvanized steel enabled us to do something that was recyclable, portable and would also survive and have longevity in a coastal environment.“

Craig Beech, Beech Architects

Two holiday homes on the Suffolk Coast that have replaced a derelict building can be moved as the coast retreats and thus react to climate change. Watch the video to find out more.