The true cost of protecting steel work from corrosion has to take into consideration two important elements:

- The initial cost of protection

- The lifetime cost, which includes the cost of maintenance. This is the cost of ensuring that steelwork is protected from corrosion throughout its service life.

What is the cost of galvanized steel?

Initial cost of galvanizing

Hot dip galvanizing is often perceived to be more expensive than it is. There are two reasons for this: Firstly, that such a high performance coating is automatically assumed to be expensive. Secondly, the initial cost of galvanising relative to paint has changed significantly over recent years. Painting costs have steadily increased whilst galvanising costs have remained stable.

Galvanizers Association commissioned independent consultants, The Steel Protection Consultancy Ltd (SPC), to investigate the galvanising prices and the cost competitiveness of galvanizing. SPC in conjunction with consulting engineers, WS Atkins, designed a typical, 240 tonne, steel-framed building and sent it out to tender.

The paint system was found to be 35% more expensive than hot dip galvanizing.

Two corrosion protection systems were specified; (i) hot dip galvanizing and (ii) a good quality, grit blast and three coat paint system of 250µm dry film thickness. Quotations from eight fabricators in different parts of the UK were obtained and averaged. The paint system was found to be 35% more expensive than hot dip galvanizing.

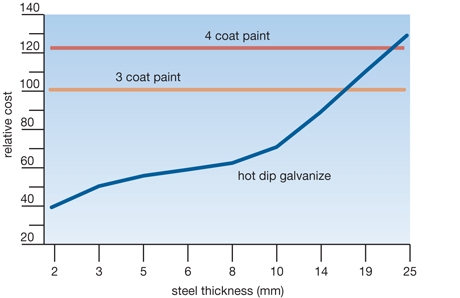

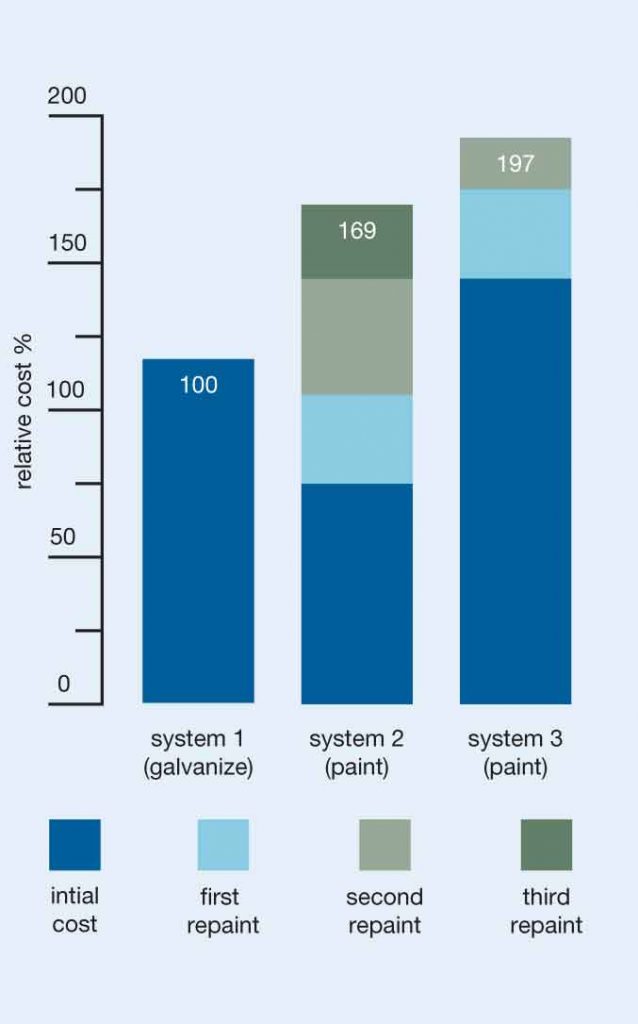

Figure 1. Comparisons between initial costs for hot dip galvanizing and paint

Figure 1 illustrates that for many applications the cost of hot dip galvanizing is lower than that of applying alternative coatings. The reason for this is simple: alternatives such as painting are very labour intensive compared with galvanizing, which is a highly mechanised, closely controlled, factory process.

Whole-life cost

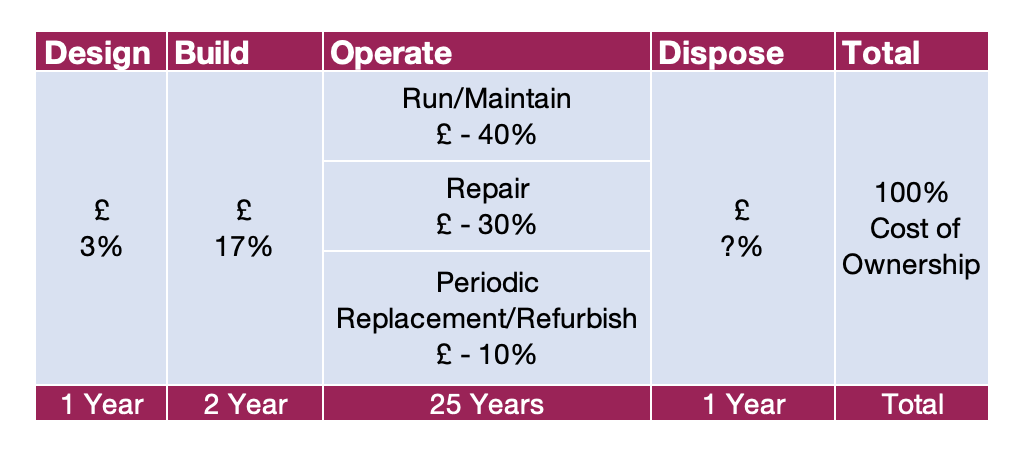

The whole-life cost of a building can be defined as: “The cost of acquiring, operating and maintaining a building over its whole life through to disposal”.

Capturing Whole Life Costs for a Building

Whole-life costing can be characterised as a system that quantifies financial values for buildings from inception and throughout the building’s life. It is an approach that balances capital with revenue costs to achieve an optimum solution over a building’s whole life.

This technique, whilst not in itself new, has over recent years become accepted best practice in construction procurement. Whole-life costing can be used at any stage of the procurement process and can be used at the levels of facility, function, system and component. This includes everything from initial design to end-of-life.

Capturing whole-life cost

It is estimated that up to 80% of a building’s whole-life cost can be attributed to running, maintenance and refurbishment costs. Consequently, there are spikes in expenditure at 10 years and every five years after that.

It is estimated that up to 80% of a building’s whole-life cost can be attributed to running, maintenance and refurbishment costs. Consequently, there are spikes in expenditure at 10 years and every five years after that.

The initial choice of materials and the way that they are protected obviously plays an important role within the maintenance and refurbishment costs of a building over its lifetime. They therefore have a very large influence on the whole-life cost profile of the project.

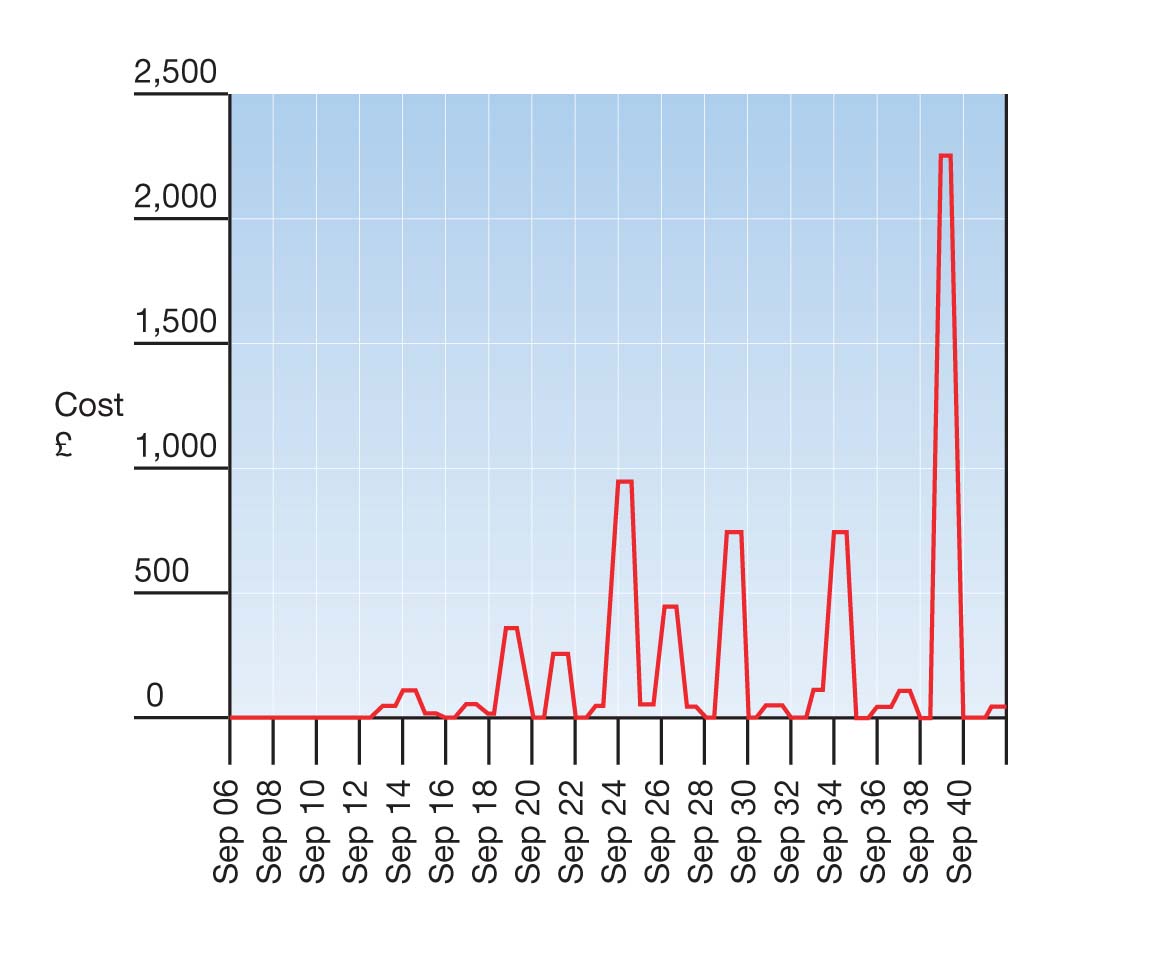

Smoothing the expenditure

Life cycle expenditure tends to inherently produce ‘spiky’ profiles with large peaks at 10, 15, 20 and 25 years. Information supplied by Turner and Townsend, Construction and Management Consultants.

Lifetime galvanizing costs

The overall cost of protecting a steel fabrication throughout its life depends on the cost and durability of the initial coating in the particular environment and, on the costs and frequency of any subsequent treatments where the required life exceeds that of the initial coating.

In the majority of applications, hot dip galvanizing will provide a long, maintenance-free life without any requirement for maintenance painting.

There are ways of calculating the benefits or disadvantages of different methods of corrosion protection. The most common method is to calculate the Net Present Value (NPV) of each method and compare the results. This calculation takes into account the cost of borrowing money, the initial cost of protection, subsequent maintenance costs and the lifetime of the project.

It is frequently used by companies to measure the likely outcome of a capital investment project.

Example

Take the case of a steel structure that has a projected life of 25 years and for which the discount cost of capital is 5%.

Galvanize: system 1

Galvanize: system 1

Hot dip galvanize to BS EN ISO 1461 with a minimum average coating of 85µm on steel of 6mm or more thick. As galvanizing to this standard has an average life expectancy of more than 50 years in the UK, it is very conservative to project a life of 25 years without further maintenance. Let the cost of galvanizing be a base figure of 100 units. There are no further maintenance costs. (NPV = 100)

Paint: system 2

A paint system consisting of cleaning followed by an undercoat and two top coats of paint. This system has a life expectancy of eight years and so will need be repainted three times in 25 years. The initial cost is slightly cheaper than hot dip galvanizing at 90 units. The cost of repainting for the first two occasions is 45 units but goes up to 90 units for the third repaint when the original paint must be removed. (NPV = 169)

Paint: system 3

A superior paint system consisting of blast cleaning followed by three coats of a higher quality paint. This system has a life expectancy of 11 years and will need to be repainted twice in 25 years. The initial cost is higher than the other paint system at 135 units. The cost of repainting is half this value at 67.5 units. (NPV = 197.5)

Conclusion: is galvanised steel expensive?

It can be seen that over a 25-year project life the cost of a “cheaper” paint system is almost 70% more than the cost of galvanizing.

A “cheaper” paint system is almost 70% more than the cost of galvanizing.

Likewise the cost of a more “expensive” paint system is almost double that of galvanized steel. In initial, or first, cost terms hot dip galvanizing is comparative with a good quality paint system. However, when looking at lifetime costs, hot dip galvanizing works out to be considerably cheaper than most other systems.