What is galvanised steel used for?

With a history that stretches back over 150 years, there are innumerable examples of galvanised steel in use in many environments, which prove its performance.

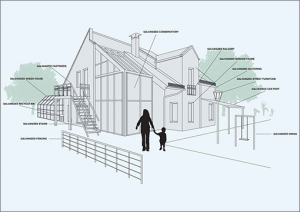

Galvanized steel is all around us, in a whole variety of industries including road, rail, energy plants, oil and gas, agriculture, water and waste and sports and leisure. It can play an important role for buildings, bridges, facades, signal gantries, gates, balconies and even sculptures. Wherever there is a risk for corrosion of steel, galvanising should be used.

What are the advantages of galvanized steel?

Hot dip galvanizing steel offers many advantages and benefits: it’s proven, honest, sustainable and more. Find out below why it is crucial to galvanise steel.

1. Galvanizing is Durable

A galvanized coating is one of the most durable forms of corrosion protection on the market.

An average coating thickness of 85 microns, the same thickness as a sheet of A4 paper, can protect a steel structure for the better part of 100 years.

One of the inherent benefits of hot dip galvanizing is that when clean steel that is greater than 6mm thick is submerged into molten zinc, it will develop a minimum mean coating of 85 microns. This coating thickness will meet the corrosion performance required in many applications across the UK and Ireland today.

In inland areas across the UK and Ireland, a galvanized coating can weather at less than one micron per year, giving it incredible longevity. Even in coastal environments an 85 micron coating can still deliver a life expectancy of 30 years or more.

2. Galvanizing is Sustainable

The long-term durability provided by galvanizing is achieved at relatively low environmental burden in terms of energy and other globally relevant impacts.

The long-term durability provided by galvanizing is achieved at relatively low environmental burden in terms of energy and other globally relevant impacts.

Several studies have demonstrated the high economic and environmental costs associated with the repeated maintenance painting of steel structures. These burdens can be significantly reduced by an initial investment in long-term protection. Lack of attention to optimal corrosion protection can leave a damaging economic legacy of repeated maintenance costs.

In social housing projects, future maintenance costs will be borne by the local authorities. In public infrastructure projects, use of galvanized steel leads to lower maintenance budgets, releasing public funds for other purposes.

3. Galvanizing is Cost-effective

The true cost of protecting steel work from corrosion has to take into consideration two important elements, the initial cost of protection and the lifetime cost.

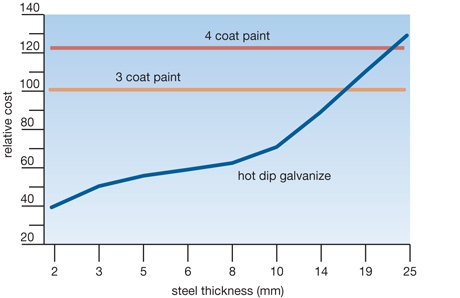

Hot dip galvanizing is often perceived to be more expensive than it is. There are two reasons for this: Firstly, that such a high performance coating is automatically assumed to be expensive. Secondly, the initial cost of galvanising relative to paint has changed significantly over recent years. Painting costs have steadily increased whilst galvanising costs have remained stable.

Galvanizers Association commissioned independent consultants, The Steel Protection Consultancy Ltd (SPC), to investigate galvanising prices and the cost competitiveness of galvanizing. SPC in conjunction with consulting engineers, WS Atkins, designed a typical, 240 tonne, steel-framed building and sent it out to tender.

Two corrosion protection systems were specified; (i) hot dip galvanizing and (ii) a good quality, grit blast and three coat paint system of 250µm dry film thickness. Quotations from eight fabricators in different parts of the UK were obtained and averaged. The paint system was found to be 35% more expensive than hot dip galvanizing.

- Read more on galvanized steel cost

4. Galvanizing is Proven

Galvanizing is all around us, with the galvanising industry recording increased production year on year. From the smallest components to the largest structural elements, galvanized steel proves itself time and time again as trustworthy and reliable.

As an industry, UK and Irish galvanizers can point to a history spanning over one hundred and sixty years. Many plants have been in the same family for generations, protecting built assets for decades.

It is an industry built upon track record and proven performance, which is rigorously tested through expert monitoring and performance data collection.

The UK is the only country worldwide to have a national corrosion map, The Atmospheric Corrosion Rate of Hot Dip Galvanizing, which shows clear evidence-based performance data for an 85 micron, batch hot dip galvanized coating.

The corrosion map provides a background corrosion rate for every 10km2 across the UK, meaning that specifiers can have confidence they are getting the right protection for their steelwork.

- View our handy Corrosion map for corrosion rates in your area

5. Galvanizing is Reliable

Galvanizing is a relatively straightforward and closely controlled process. The coating formed is consistent, predictable and simply specified.

Hot dip galvanizing is defined by a single standard – EN ISO 1461.

There are a number of reasons why galvanising steel is the most reliable form of corrosion protection. Firstly, as a natural metallurgical reaction – a function of introducing clean steel into molten zinc at a specified temperature – galvanizing is a replicable process.

Unlike a paint coating, the metallurgical bond that is formed through galvanizing becomes part of the steel itself and is not merely a chemical or mechanical bond.

As a natural reaction, galvanizing occurs automatically and does not rely on manual application, or require cooling and reapplication of additional layers. The resultant galvanised coating protects steel from day one and can be depended upon for generations.

We have embarked on creating an archive of case histories. This will feature a broad range of projects, locations and encompass details from coating thickness measurements to coating aesthetics.

6. Galvanizing is Honest

Corrosion protection that works from day one. If your galvanized coating is there you can be sure it is working. With hot dip galvanizing seeing is indeed believing.

Due to the metallurgical bond that is formed when steel is dipped into molten zinc, a galvanized coating offers straightforward, secure protection from the get-go. Hot dip galvanizing requires rust-free, uncontaminated steel for the process to occur. Once the coating is present, it is impossible for it to fail from underneath. Other coatings can adhere to residual contaminants, this can undermine performance, lead to flaking and cause premature failure.

If you can see a continuous galvanized coating on day one, you can be confident of long term protection.

Over a matter of months or years, the initial bright, silvery finish will change to form a duller patina as the surface reacts with oxygen, water and carbon dioxide. A complex but tough, stable, protective layer is formed which is tightly adherent to the zinc.

- Lewis Glucksman Gallery – 2018

7. Galvanizing is Predictable

A galvanized coating offers predictable corrosion protection that weathers in a linear fashion. Coating thicknesses are measurable and offer lifespans that can be easily forecast and relied upon.

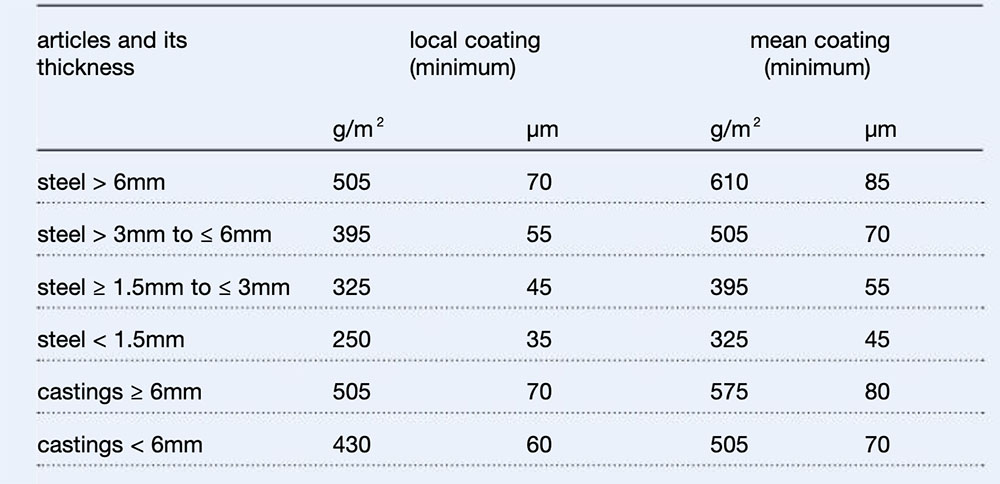

Batch hot dip galvanizing is a standardized process which produces a quantifiable coating thickness. The coating is simply specified through British, European and international standards.

The coating thickness depends upon the gauge of the steel that is galvanized and is produced consistently across the component, both inside and out. This can be measured easily throughout its lifetime, using non-destructive methods.

Galvanized steel coating minimum masses/ thickness on articles that are not centrifuged.

Galvanized steel coating minimum masses/ thickness on articles that are not centrifuged.

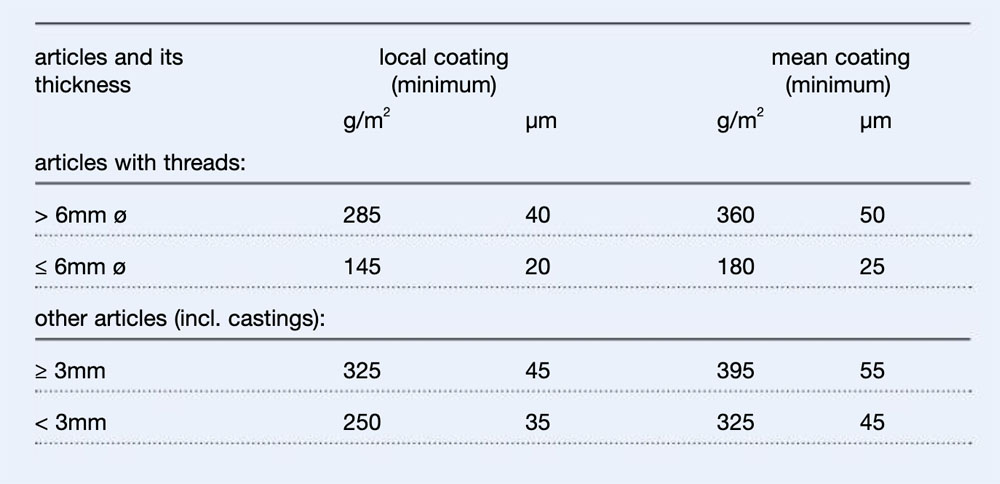

Galvanized steel coating minimum masses/ thickness on articles that are centrifuged

Galvanized steel coating minimum masses/ thickness on articles that are centrifuged

Galvanizing weathers in a predictable, linear fashion. This guarantees that if climactic conditions are stable, the lifespan of a galvanized coating can be correctly forecast, and there will be no unexpected surprises.

The lifespan of the coating is also exceptionally long compared with other forms of corrosion protection and will weather at less than one micron per year in certain climates. The local rate of weathering of any given galvanized coating can be reliably calculated.

Atmospheric corrosion maps dating back to the 1960s and the inherent linear rate of depletion of the coating mean that highly accurate performance data can be ascertained at the most local level. Check your corrosion rate here.

8. Galvanizing Offers Complete Coverage

Hot dip galvanizing creates a very strong bond between zinc and steel, forming a coating that will last for generations. Alongside superior strength comes superior coverage, so that galvanized steel structures remain protected, even in their most vulnerable areas.

There are multiple reasons why hot dip galvanizing outperforms other organic coatings. A crucial factor is the way the process achieves complete coverage of a component, both inside and out.

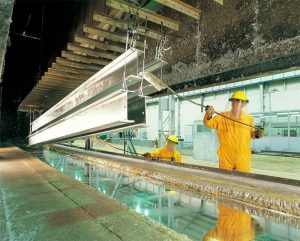

After an initial cleaning cycle, clean iron or steel components are immersed into molten zinc, commonly at around 450°C. The rate of reaction is rapid and a typical time for immersion is only a few minutes. Heavier articles with a high thermal inertia may take longer.

The dipping of steel into a tank of molten zinc via the hot dip galvanizing process means the zinc can access even the trickiest areas.

A further benefit of hot dip galvanizing is that hollow components are coated on internal surfaces too, meaning that a structure will not corrode from the inside out. In addition, the coating will also build up at vital corners and edges, unlike brushed or sprayed coatings, which traditionally thin out in these areas.

Hot dip galvanizing is used equally for small components, making sure they are given the same level of corrosion protection as larger articles. Complete structures receive complete corrosion protection.

- Learn how you can stop rust and view corroding steel across UK and Ireland

-

Read about the History of Galvanizing

which spans over 300 years

9. Galvanizing is Tough

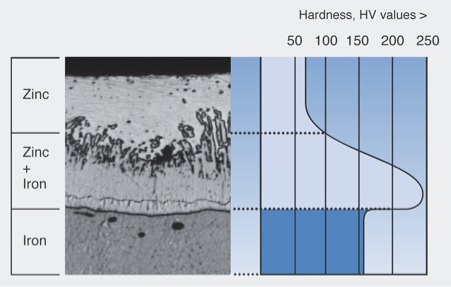

Galvanizing has an abrasion resistance up to ten times better than organic paint coatings. The hot dip process is unique, producing a coating which is bonded metallurgically to the steel. As a result, galvanized steel has superior resistance to mechanical damage during handling, storage, transport and erection.

Due to its unique metallurgical bond, a galvanized coating is incredibly tough, offering exceptional performance across multiple layers. An initial outer layer provides reliability as a buffer zone, helping to absorb any initial shock to the coating.

Underlying zinc-iron alloys can be harder than mild steel itself, and will further reduce any potential penetration of the coating or the exposure of bare steel. This means that a galvanized coating is highly chip resistant and particularly suited to areas of high frequency industrial wear.

A galvanized coating can also help prevent damage during construction, where its toughness can protect components during transport, erection and the other mechanical activities.

Overall a galvanized coating has a high corrosion prevention value. It is extremely hardwearing, long-lived and suited to applications where both mechanical and corrosive protection are paramount.

- Learn more about the galvanizing process and its properties

10. Galvanizing Offers Three Way Protection

Hot Dip Galvanizing protects valuable assets in multiple ways and has considerable economic and environmental benefits.

It is the most durable corrosion protection on the market, and provides optimum performance without the expense or disruption of maintenance procedures. There are three ways a galvanized coating will protect your steel.

1. A Physical Barrier

A galvanized coating provides a physical barrier which is metallurgically bonded, and prevents the underlying steel from being exposed to atmospheric conditions.

This coating is highly durable and has an adhesive strength of up to seven times that of organic paint coatings. It is a robust, physical barrier comprising of a softer, zinc, outer layer which will absorb initial impact loading and underlying layers of strong metallurgically bonded alloys.

These alloys are often harder than the original steel they protect and offer excellent abrasion and chip resistance. As a protective barrier, a galvanized coating weathers at a slow rate and can easily provide corrosion protection for over 60 years, maintenance free.

2. Sacrificial Protection

A galvanized coating will corrode preferentially and slowly. Small scratches on a galvanized surface will not normally require any repair work, and if small areas do become exposed to humidity and other corrosive elements, the galvanized coating will corrode preferentially and at a slower rate than the underlying steel.

This type of protection is called cathodic protection and means the coating will sacrifice itself before it allows the steel to be compromised. It is a key function of the long-term protection offered by hot dip galvanizing.

3. Prevention of sideways creep

In the unusual event that a galvanized coating is locally compromised and bare steel is exposed, the zinc coating will limit damage and prevent a form of corrosion known as sideways creep.

Sideways creep can severely undermine paint coatings and is caused as rust deposits accumulate on bare steel and spread underneath and across the paint film. Left untreated, sideways creep will produce peeling and the eventual breakdown of the paint coating. Hot dip galvanizing prevents this kind of deterioration.

11. Galvanizing has a Fast Turnaround

With the right communication you can get steel galvanized within 24 hours.

Galvanizing is not a time-consuming process and in reality, it takes just a few minutes to dip prepared steelwork into molten zinc to form a durable, reliable coating.

Preparation of the steel need not take long either, but it must be thorough. Plus, if your galvanizing is prioritised in the same way that other parts of a project are, hot dip galvanizing will be a seamless, time-efficient process.

The actual process of dipping steel in molten zinc is in itself a straightforward, relatively immediate process, but for maximum efficiency, simple preparation is required.

Firstly, steel must be grease and corrosion free, so it is hung on jigs and cleaned, rinsed and fluxed. It is then dipped into a galvanizing bath of molten zinc at a temperature of 450°C, before it is left to cool.

By arrangement, it is likely possible in 24 hours.

The metallurgical reaction occurs in a matter of minutes, with the whole galvanizing procedure taking only a few hours. In practice of course, there are many orders being processed at a galvanizing plant at any one time, so the typical turnaround for hot dip galvanizing is about three days.

Today’s galvanizing plants have highly efficient logistics in place, meaning that your steelwork can be galvanized in as little as 24 hours if arranged in advance.

Turnaround time can be minimized if you follow a few simple steps.

- It pays to communicate with your galvanizer and a quick phone call a few days ahead is all it requires to plan work into a busy galvanizing schedule.

- Sending in ‘clean’ steelwork will save preparation time. Work that is contaminated with material which will not be removed by the normal galvanizing pre-treatment, will need special steps to remove it.

- The same applies for venting and drainage. As a dip process, galvanizing will protect the inside of steel sections as well as the outside, these holes are in the right places. Ensuring that there are correct vent and drain holes in hollow steelwork, saves the galvanizer valuable time, as they would have to complete that work for you.

- Finally, it pays to liaise on transport. If the galvanizer is providing transport, liaise about the regular runs and plan around them. Galvanized steelwork may even be able to go directly to site.

Where can you galvanise steel?

The design of the component may be important for successful galvanizing and early consultation between galvanizer, fabricator and designer is the key to obtaining the best result.

The bath dimensions noted within the galvanizers directory (link below) indicate the length, depth and width of the galvanizing bath(s) at each works. These bath dimensions give an indication of maximum size of fabrication which can be processed at that plant.

It is important to recognise that these dimensions do not, in themselves, represent the maximum size of fabrication which can be dipped.

Find out more details and see who your local galvanizer is.