The European and International standard covering post-fabrication hot dip galvanizing of steelwork, EN ISO 1461 – Hot Dip Galvanized Coatings on Fabricated Iron and Steel Articles – Specifications and Test Methods has been revised, with the new version of the standard published in 2022. The revision of EN ISO 1461 was initiated to make improvements to the standard and to align it with the latest developments from within the industry.

EN ISO 1461 contains requirements for the hot dip galvanized coating thicknesses which are proportional to the section thickness of the steel being galvanized. For example, for steel greater than 6 mm thick, the minimum mean coating thickness requirement is 85 microns, which offers a very high level of corrosion protection in most service environments. The actual thickness of galvanized coating achieved varies with steel section size, surface profile and surface composition. In practice, coating thicknesses are often much more than the minimum specified in this standard.

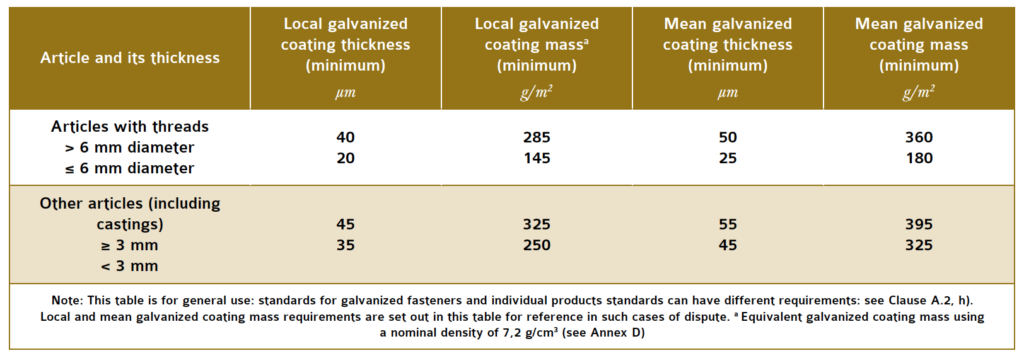

Minimum galvanized coating thickness and mass on samples that are not centrifuged.

Thicker coatings than those set out in EN ISO 1461 can offer additional protection for use in particularly aggressive environments and can be specified in conjunction with EN ISO 1461. It should, however, be emphasised that for most applications, thicker coatings are rarely necessary. The standard includes the surface finish requirements of the galvanized coating, such that it should be continuous and relatively smooth (i.e., no spikes or sharp edges). Variation in coating appearance (e.g., cellular pattern or dark grey areas) or some surface unevenness is not cause for a rejection; these are inherent properties of hot dip galvanizing and are typically determined by the steel’s reactivity.

Minimum galvanized coating thickness and mass on samples that are centrifuged.

A detailed inspection procedure is also outlined which includes the number of reference areas which are to be taken on each article, and the number of articles which are to be included in the control sample. This ensures that a thorough, non-destructive, statistical analysis is conducted across galvanized articles. The most significant changes to EN ISO 1461 concern the galvanizing of ultra-low reactive steels, coating thickness measurements on ancillary elements, removal of flux residues and zinc ash, the renovation of galvanized steelwork and reference to long term performance of galvanized coatings in atmospheric environments. There has been no fundamental change to the method of assessment of coating thickness, but allowances for measurements on ancillary elements and ultra-low reactive steels have been introduced. The revised standard states that thickness measurements should not be taken on ancillary elements (e.g., brackets) unless specifically requested.

Recognition that certain steel compositions can exhibit ultra-low reactivity during galvanizing (i.e., cannot satisfy the standard minimum coating thickness requirements) has been introduced. Articles produced from steel with a section thickness greater than 3 mm which have a composition of ≤ 0.01 % silicon AND an aluminium content > 0.035 %, that exhibit ultra-low reactivity during galvanizing, can now be subject to lower coating thickness requirements. The variation to the standard requirements must be included in the Declaration of Compliance if one is to be provided.

The updated version of the standard now acknowledges that if ‘access is restricted, for example, inside hollow sections’ flux residues and zinc ash are permissible. The guidance offered on the renovation of uncoated or damaged areas is now more extensive and includes detailed specifications for zinc-containing paints, commonly used to repair galvanized coatings in the unlikely event of damage or an uncoated area post galvanizing. EN ISO 1461:2022 now references ISO 9224 – Corrosion of metals and alloys – Corrosivity of atmospheres – Guiding values for the corrosivity categories in the Annex ‘Corrosion resistance of galvanized coatings.’ ISO 9224 provides information on the average and steady-state zinc corrosion rates which are useful for predicting long-term performance of galvanized coatings in atmospheric environments. Long-term corrosion rates for zinc are lower than first year corrosion rates because of the development of a protective patina formed on the initial galvanized coating over time. For most applications, where galvanized steel articles are exposed to atmospheric conditions, the galvanized coating life in those conditions is proportional to the thickness of the galvanized coating.

The revised standard has been welcomed by industry and the specifying marketplace, owing to the up-to-date information and comprehensive improvements to the relevant sections.

Image:Studio Bowie