Galvanizers Association provides free advice and technical information to anyone looking to specify hot dip galvanizing. We can offer assistance with your design and fabrication to ensure a good solution for your client. To find one of our member galvanizers in your area, just select your location from the menu below.

Where are you looking to conduct galvanizing?

Most sizes and shapes of steel fabrications can be hot dip galvanized, but the dimensions of the galvanizing bath determine the size and shape of articles that can be coated in a particular works.

1. Design principles

The design of the component may be important for successful galvanizing and early consultation between galvanizer, fabricator and designer is the key to obtaining the best result. Design features which aid the access and drainage of molten zinc will improve the quality of the coating (refer to Designing Articles for Galvanizing).2. Bath Dimensions

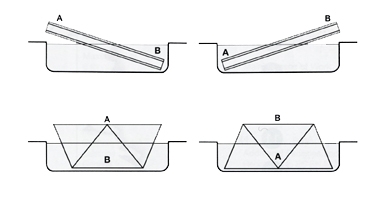

The bath dimensions noted within the following pages indicate the length, depth and width of the galvanizing bath(s) at each works. These bath dimensions give an indication of maximum size of fabrication which can be processed at that plant. It is important to recognise that these dimensions do not, in themselves, represent the maximum size of fabrication which can be dipped. The precise maximum single dip size can be agreed with the galvanizer and will usually depend upon the angle of immersion and overall dimensions of the fabrication.3. Size and shape of fabrications

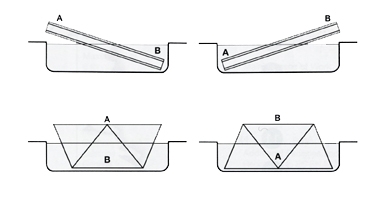

Articles which are larger than the bath dimensions can sometimes be galvanized by “double-dipping”. Here, the article is partially dipped in the zinc, removed, reversed for length or depth to allow dipping of previously un-coated section. Although generally it is preferable to process work in single dip, the corrosion protection afforded through double dipping is no different to that provided in a single dip. Sizes of articles which can be double-dipped should always be agreed with the galvanizer.