In 2005 Galvanizers Association in conjunction with European General Galvanizers Association (EGGA) contracted Life Cycle Engineering (LCE), Torino, Italy to perform a pan-European life cycle inventory (LCI) study of hot dip galvanized products. The study considered an average result for typical general galvanized products but a separate product class was identified for highway guard rails.

The objective of the work was to deliver life cycle inventory data sets for the galvanizing process, sometimes known as ‘the service’, using data submitted by members of EGGA National Associations from their members’ operations.

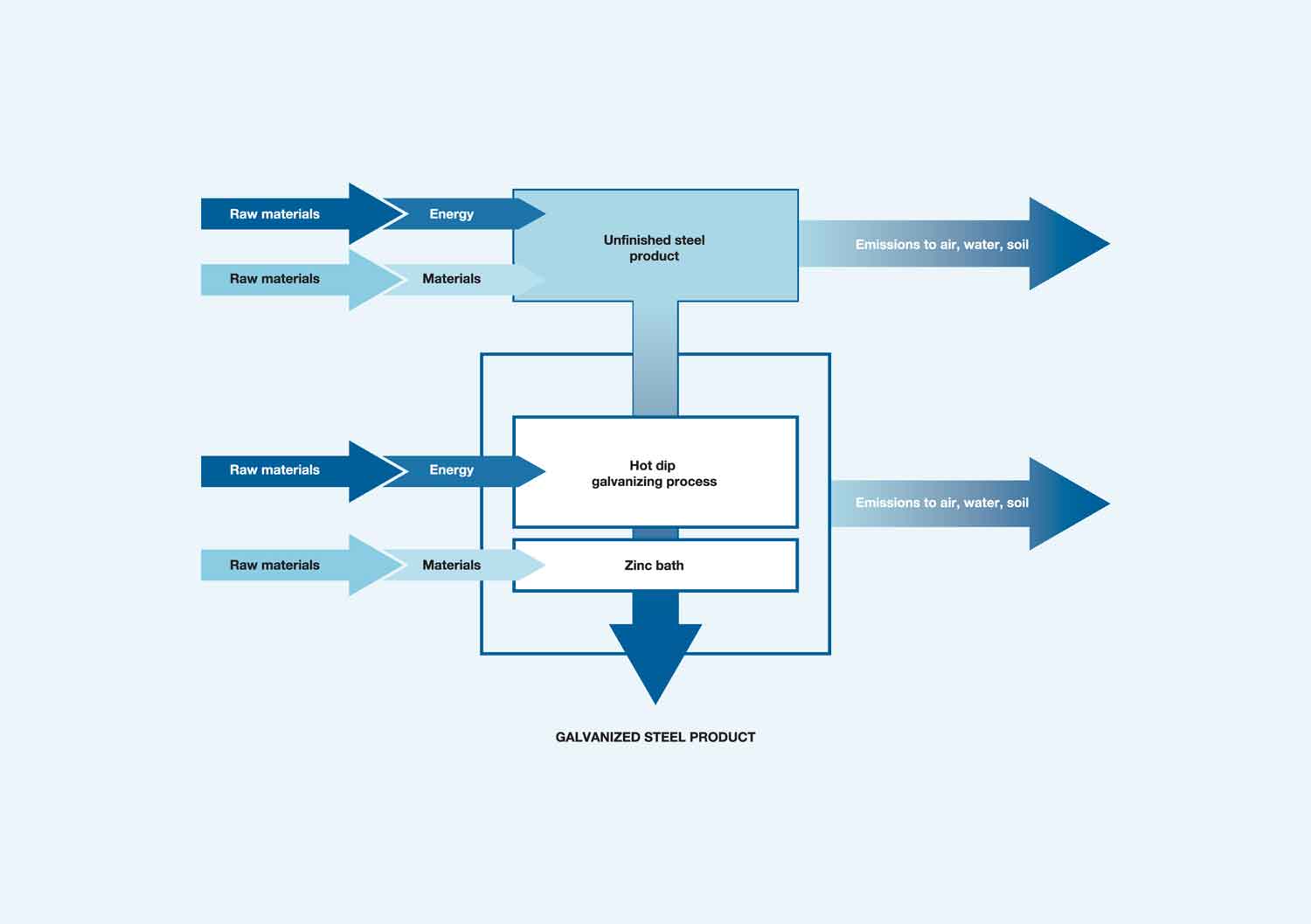

This involved quantifying the average energy, resource consumption and emission of substances to the environment, resulting in an LCI of a sample of processes operating in several plants in Europe, according to the defined system boundaries. The sample covered about 937,000 tonnes of steel galvanized by 46 plants.

The systems under consideration have the purpose of processing steel pieces and elements products to protect the surface of the steel from the environment.

The functional unit was thus expressed in terms of 1 tonne of averaged zinc coated steel product.

Life cycle inventory for general galvanizing – LCI: system overview

Energy and environmental results are expressed by reference to the functional unit, but an extension of the analysis provides data about the system, independently of the steel product, in order to focus attention on ‘the service’.

Such results were expressed in terms of ‘1kg of zinc alloy ready for coating purposes’. This represents a useful measure of the energy and environmental costs of ‘the service’.

This LCI data is available, on request from GA, to LCA professionals and customers who wish to generate an environmental product declaration for a galvanized steel construction product.